Lower Waste Costs with OEM Solutions from Top Manufacturers and Factories

As an expert in waste management solutions, I recognize the critical importance of managing waste costs efficiently. Our tailored offerings for OEMs, factories, and suppliers leverage innovative technologies that optimize waste disposal processes. With an emphasis on reducing operational expenses and promoting environmental sustainability, our systems are engineered to enhance the efficiency of your waste management practices.Proven Methods To Waste Costs Industry Giant Market Leader

In today's competitive landscape, cost-effective strategies are paramount for procurement leaders looking to optimize operations. The Organic Waste management sector is evolving rapidly, driven by technological advancements and an increasing global emphasis on sustainability. Companies that embrace innovative methods can drastically minimize expenses while enhancing their environmental impact. Proven techniques such as the utilization of smart waste sorting systems, advanced composting technologies, and biogas recovery not only streamline processes but also contribute to significant long-term savings. Implementing these solutions allows businesses to convert potential waste into valuable resources, such as energy or compost, thus creating a circular economy. This approach not only mitigates disposal costs but also aligns with global sustainability targets, making it an attractive proposition for organizations committed to reducing their carbon footprint. Furthermore, leveraging data analytics can optimize route planning and logistics, ensuring that waste is collected and processed in the most efficient manner. As industry standards shift towards sustainable practices, securing a partner that prioritizes innovation in organic waste management is essential for global buyers. By investing in proven methods, companies can enhance their operational efficiency, reduce costs, and meet the increasing demands for eco-friendly solutions across the marketplace.

Proven Methods To Waste Costs Industry Giant Market Leader

| Cost Reduction Method | Description | Estimated Savings (%) | Implementation Time (Months) |

|---|---|---|---|

| Lean Manufacturing | Eliminate waste through continuous improvement and efficient process flows. | 20% | 6 |

| Supply Chain Optimization | Streamline supply chain activities to reduce costs and improve efficiency. | 15% | 3 |

| Energy Efficiency Programs | Implement energy-saving initiatives to lower utility costs. | 10% | 2 |

| Automated Processes | Utilize technology to automate repetitive tasks and reduce labor costs. | 25% | 12 |

| Outsourcing Non-Core Activities | Contract out functions that are not central to the business strategy. | 18% | 4 |

10 Essential Tips For Waste Costs Industry Giant Manufacturer

S

Sarah Johnson

This product is fantastic. The after-sales service was proactive and very professional.

25 May 2025

T

Thomas Richard

Top quality product! Their follow-up service was professional and reassuring.

18 May 2025

J

Jason Lewis

Amazing quality and great service! Their after-sales team made everything seamless.

03 June 2025

K

Kevin Price

Impressed by the quality! Their after-sales service was professional and quick.

05 June 2025

Z

Zoe Mitchell

Impressive quality! The professionalism showed by the after-sales team was commendable.

05 June 2025

C

Chloe Reed

Very high-quality product! The professionalism and attentiveness of the customer service were remarkable.

10 May 2025

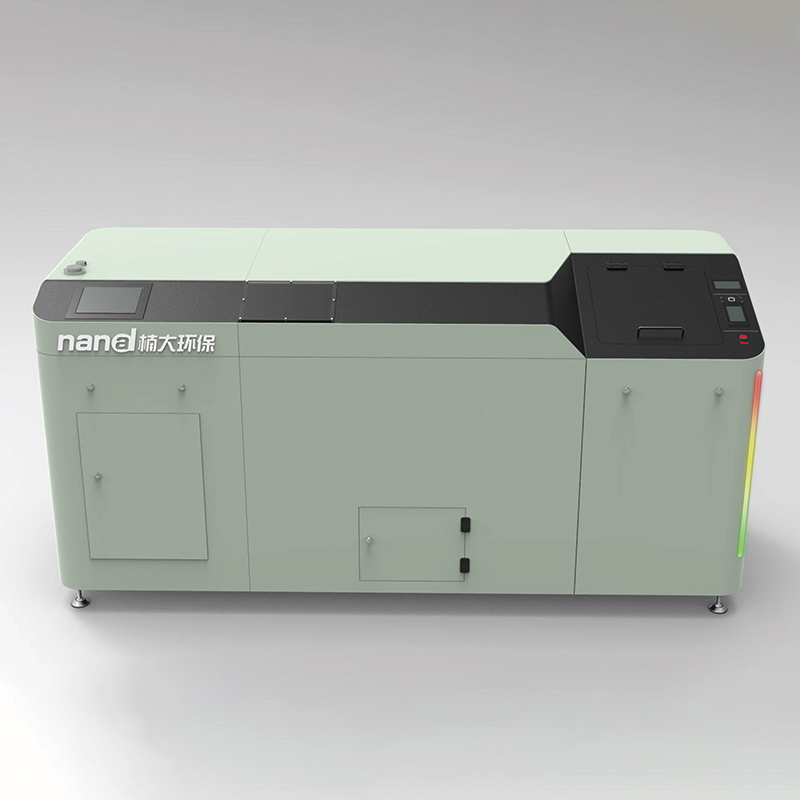

Nanda Trans Series-200

Nanda Trans Series-200 Nanda Trans Series-500

Nanda Trans Series-500 Nanda Trans Series-1000

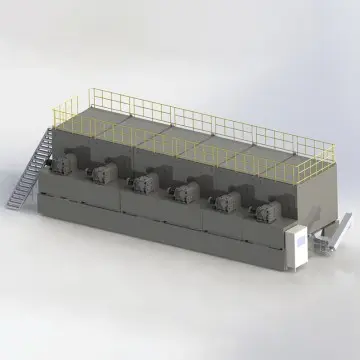

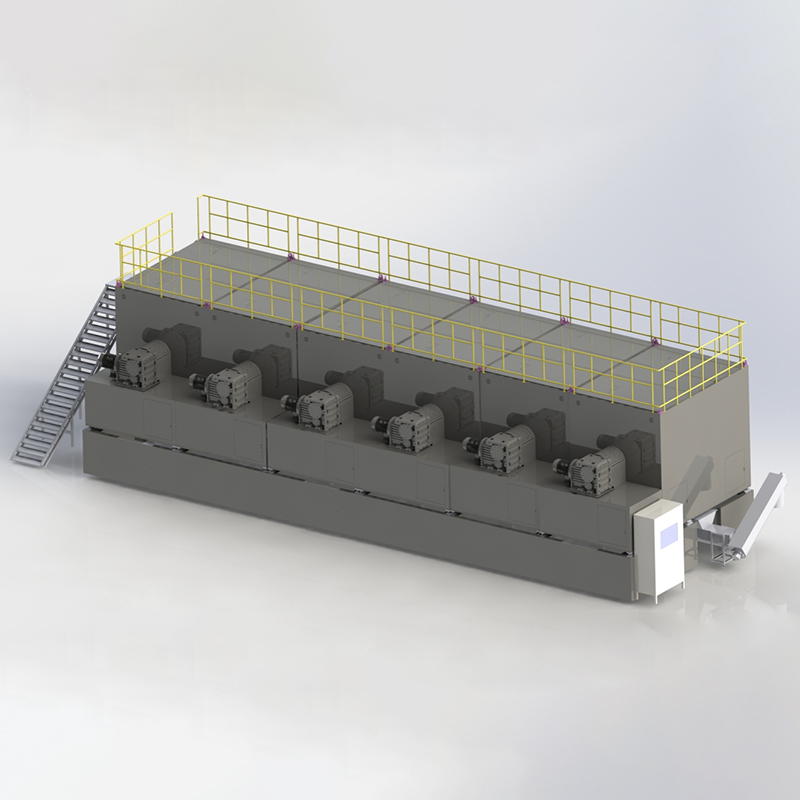

Nanda Trans Series-1000 Nanda Trans Series-30000

Nanda Trans Series-30000 Nanda Thermax Series-100

Nanda Thermax Series-100 Nanda Thermax Series-200

Nanda Thermax Series-200 Nanda Thermax Series-2000

Nanda Thermax Series-2000 Nanda Thermax Series-10000

Nanda Thermax Series-10000 Nanda Turbo Series-3.5L-016

Nanda Turbo Series-3.5L-016 Nanda-Turbo Series-4L-011

Nanda-Turbo Series-4L-011 Nanda Turbo Series-4L-012

Nanda Turbo Series-4L-012 Oil-Water Separator

Oil-Water Separator