NanDa Technology and Hangzhou Environmental Group Jointly Complete Pilot Project for Kitchen Waste Reduction and Resource Utilization

The disposal of household food waste has long been a persistent environmental challenge. Difficulties in Reducing Waste volume, low returns from resource recovery, and high costs associated with off-site incineration have led to reliance on compression-dewatering followed by incineration. This approach not only triggers the “not-in-my-backyard effect” due to secondary transportation but also results in significant resource wastage. Today, encouraging news from a pilot project in Hangzhou's urban core offers fresh hope for solving this problem.

I. Joint Pilot Test Success: Hardcore Data Redefines Processing Efficiency

Recently, Hangzhou Nanda Environmental Technology Co., Ltd. (hereinafter referred to as “Nanda Technology”) and the Resource Utilization Division of Hangzhou Environmental Group have joined forces to successfully complete a two-month pilot-scale validation of the “Ambient Temperature Aerobic Biological Hydrolysis Technology” at the Tianzi Ling Circular Economy Industrial Park. This project targets solid organic matter from kitchen waste (after leachate separation) in Hangzhou's main urban area.

This pilot test, jointly led by both parties, yielded remarkable results and delivered an impressive “report card”:

- Achieved a solid reduction rate of 83.24%, fully demonstrating the technology's exceptional capability in source reduction.

- The average oil content in the bio-hydrolysate reached 3.15%, providing high-quality feedstock for subsequent production of green energy such as biodiesel and significantly enhancing resource utilization value.

Notably, this jointly validated research outcome has been accepted for publication in the authoritative domestic academic journal China Journal of Resource Comprehensive Utilization. This signifies that the pilot test data and conclusions have received third-party academic recognition.

II. Core Technology: High-Efficiency Microorganism-Driven “Waste Transformation Process”

Why did NanDa Technology's “Ambient Temperature Aerobic Biological Hydrolysis Technology” perform so exceptionally well in this joint validation? Its core lies in utilizing a proprietary high-efficiency microbial inoculant to rapidly decompose insoluble solid organic matter into small-molecule soluble substances (biological hydrolysis liquid) under ambient temperature and ventilation conditions. This liquid then enters the oil extraction system via the liquid collection system, significantly boosting the project's oil recovery rate. After oil extraction, the hydrolysate enters the existing CSTR anaerobic system for fermentation and biogas production, greatly enhancing the resource utilization efficiency of food waste.

High Efficiency and Rapid Processing

Waste undergoes anaerobic treatment in approximately 30 to 45 days, whereas ambient-temperature aerobic hydrolysis requires only 3 days and enables 24-hour continuous operation. This significantly enhances processing efficiency.

Dual Benefits

The technology simultaneously achieves solid-to-liquid and solid-to-gas conversion, thereby accomplishing dual objectives: substantial source reduction and highly efficient oil recovery.

III. Future Outlook: Driving Zero-Waste City Development with a Joint Innovation Engine

The successful collaboration between Hangzhou Nanda Technology and Hangzhou Environmental Group not only validates the efficiency and practicality of ambient-temperature aerobic biological hydrolysis technology but also paves a viable path for reducing end-of-pipe disposal costs and enhancing resource utilization levels.

Innovation is the core engine of development. Moving forward, Nanda Technology looks forward to deepening collaborations with more industry partners like Hangzhou Environmental Group to advance the implementation of ambient-temperature aerobic biological hydrolysis technology across additional cities and scenarios. Together, we will inject robust technological momentum into the construction of “waste-free cities.”

Nanda Trans Series-200

Nanda Trans Series-200 Nanda Trans Series-500

Nanda Trans Series-500 Nanda Trans Series-1000

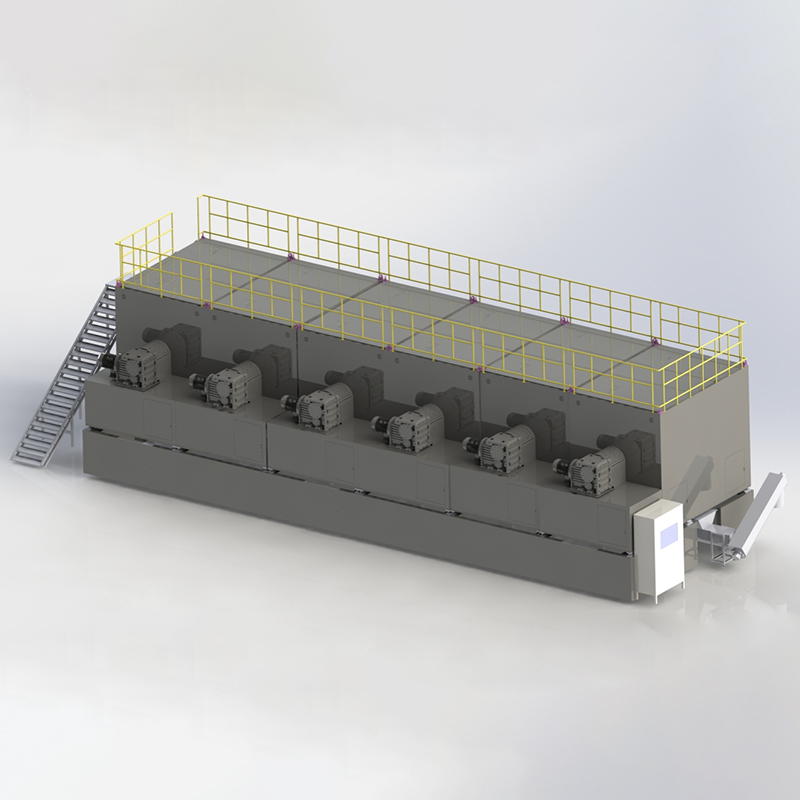

Nanda Trans Series-1000 Nanda Trans Series-30000

Nanda Trans Series-30000 Nanda Thermax Series-100

Nanda Thermax Series-100 Nanda Thermax Series-200

Nanda Thermax Series-200 Nanda Thermax Series-2000

Nanda Thermax Series-2000 Nanda Thermax Series-10000

Nanda Thermax Series-10000 Nanda Turbo Series-3.5L-016

Nanda Turbo Series-3.5L-016 Nanda-Turbo Series-4L-011

Nanda-Turbo Series-4L-011 Nanda Turbo Series-4L-012

Nanda Turbo Series-4L-012 Oil-Water Separator

Oil-Water Separator