Breaking the deadlock in food waste treatment! Nanda Technology's microbial agent system officially enters the 4.0 era.

As China's urbanization rate continues to rise, the annual production of kitchen waste has surpassed 120 million tons. Its high organic matter and high salt-oil content pose multiple challenges to traditional treatment technologies: incineration disposal results in increased energy consumption due to insufficient calorific value, while landfilling leads to leachate pollution and greenhouse gas emissions. While existing microbial treatment technologies offer environmental advantages, they are constrained by the limited functionality and environmental adaptability of microbial strains, resulting in low degradation efficiency, prolonged treatment cycles, and poor operational stability, thereby hindering large-scale application. Therefore, developing an efficient composite microbial degradation agent by screening superior strains with strong environmental adaptability and multi-substrate degradation capabilities, and constructing a synergistic microbial community with complementary functions, has become a key pathway to breaking through the technical bottlenecks in the biological treatment of Food Waste. This holds urgent practical significance for promoting the resource utilization of urban solid waste.

Technological breakthrough: multi-enzyme synergistic degradation system

Recently, the R&D team at Nanda Technology successfully developed a fourth-generation composite bacterial agent system through innovative multi-source (cow manure, leaf litter, sludge from food waste treatment stations/canteen drains, etc.) microbial enrichment screening and functional compounding technology. Compared with the previous generation of bacterial agent products, the new system offers significant improvements in all aspects of performance:

Functional Synergy: Integrates composite active components such as amylase, protease, lipase, and cellulase to achieve simultaneous degradation of the primary organic components in food waste;

Environmental Adaptability: Overcomes inhibition in high-salt (0.5–2%) and high-oil (5–20%) environments, significantly reducing microbial activation time;

Treatment Efficiency: As validated in pilot-scale testing, under conditions where the microbial agent dosage is reduced by approximately 25%, the reduction rate remains above 90%, with the treatment cycle compressed to one-third of traditional processes.

Ecological value: Technology empowering waste-free cities

1. Strengthen pollution control

Effectively block the chemical pollution of water bodies and the spread of pathogenic microorganisms by leachate, significantly suppressing the uncontrolled emission of methane. A single project can reduce carbon dioxide emissions by thousands of tons per year.

2. Promote resource recycling

Convert organic residues into bio-organic fertilizers that meet national standards, and purify waste oils into industrial raw materials, promoting the formation of a “waste-resource-product” closed loop.

3. Supporting Urban Governance

Streamline redundant supporting facilities, reduce land area, and alleviate pressure on municipal land use; lower energy consumption costs, ease the burden on urban operations, and support the implementation of the “zero-waste city” development goal.

Looking to the future: Building sustainable ecological “micro” power

Innovation is the driving force behind Nanda Technology's development and the core driving force behind the advancement of the biotechnology industry. In the future, Nanda Technology will continue to fulfill its mission of “reducing carbon emissions through technology and winning the future with intelligence,” continuously pushing the boundaries of innovation, iterating its technological products, and using microbial technology to redraw the genetic map of urban metabolism, contributing the company's wisdom and strength to the construction of a green, low-carbon, and circular economic system.

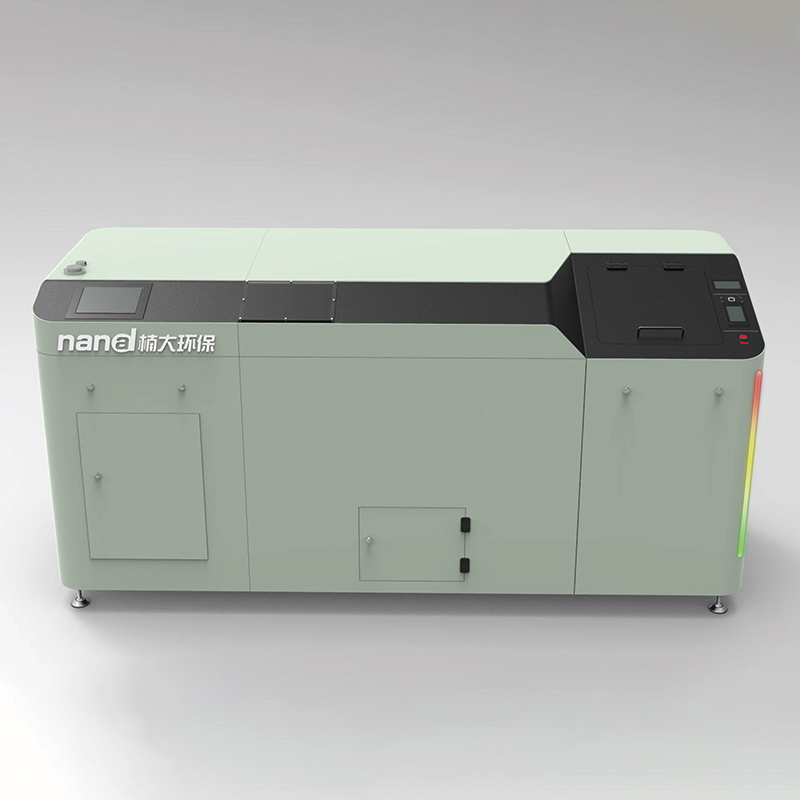

Nanda Trans Series-200

Nanda Trans Series-200 Nanda Trans Series-500

Nanda Trans Series-500 Nanda Trans Series-1000

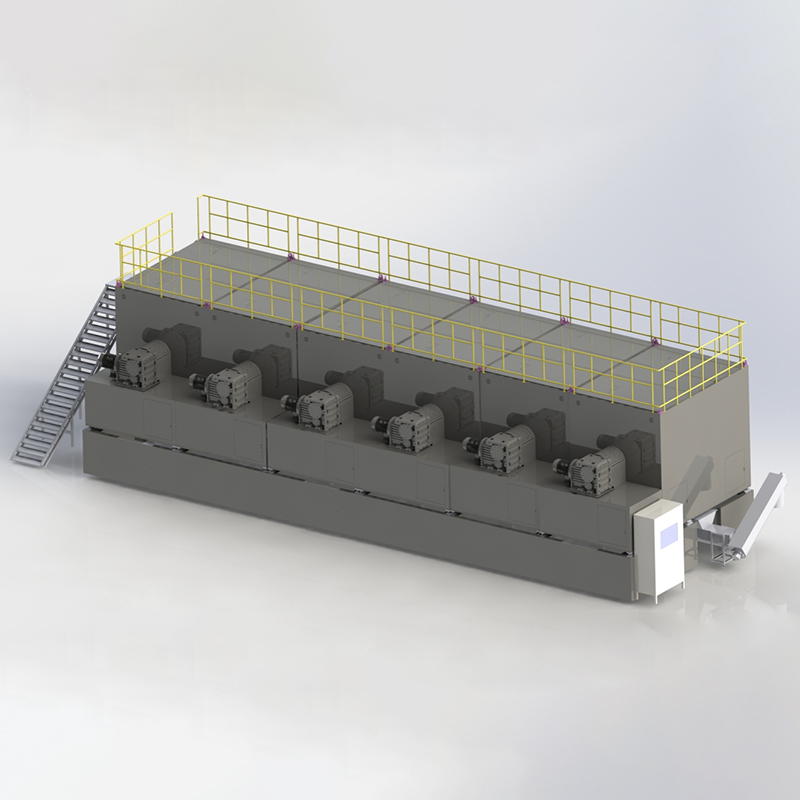

Nanda Trans Series-1000 Nanda Trans Series-30000

Nanda Trans Series-30000 Nanda Thermax Series-100

Nanda Thermax Series-100 Nanda Thermax Series-200

Nanda Thermax Series-200 Nanda Thermax Series-2000

Nanda Thermax Series-2000 Nanda Thermax Series-10000

Nanda Thermax Series-10000 Nanda Turbo Series-3.5L-016

Nanda Turbo Series-3.5L-016 Nanda-Turbo Series-4L-011

Nanda-Turbo Series-4L-011 Nanda Turbo Series-4L-012

Nanda Turbo Series-4L-012 Oil-Water Separator

Oil-Water Separator