Comprehensive Large Scale Composting Facility Solutions by Expert ODM Manufacturer

Are you seeking a dependable partner for your large scale composting facility? As a prominent manufacturer specializing in ODM solutions, we excel in innovative designs and advanced technology. Our facilities are built to enhance efficiency and sustainability, ensuring effective and environmentally friendly composting processes. We recognize the unique challenges faced by B2B purchasers, and our dedicated team is committed to providing customized solutions that fit your needs. With extensive experience, Hangzhou Nanda Environmental Protection Technology Co., Ltd. is a reliable supplier, delivering quality and dependability. Together, we can create a composting facility that meets your specific requirements while promoting a greener planet. Choose us for the finest in large scale composting technology.In-Depth Analysis of Methods Large Scale Composting Facility More Than a Supplier - A Partner Manufacturers You Can Rely On

In the rapidly evolving landscape of Organic Waste management, large-scale composting facilities are redefining their roles from mere suppliers to essential partners for manufacturers globally. This shift is driven by the increasing demand for sustainable waste solutions, requiring a collaborative approach to tackle the complexities of organic waste management. By integrating advanced technologies and innovative processes, these facilities transform waste into valuable resources, aligning with the sustainability goals of their partners. The partnership between manufacturers and composting facilities extends beyond traditional supply chains. It encompasses shared expertise, customized solutions, and a commitment to achieving sustainability targets. By working closely, these facilities can offer tailored services, ensuring that organic waste is processed efficiently and effectively. Additionally, by investing in state-of-the-art technologies, they enable manufacturers to reduce their carbon footprint while enhancing their overall operational efficiency. As global procurement professionals seek reliable partners, the importance of selecting a composting facility that prioritizes collaboration, innovation, and sustainability cannot be overstated. Engaging with a facility that understands the intricacies of organic waste management ensures not only compliance with regulations but also fosters a circular economy where waste is seen as a resource. In this dynamic environment, manufacturers can find allies in composting facilities committed to shaping a greener future, paving the way for a sustainable industry transformation.

In-Depth Analysis of Methods Large Scale Composting Facility More Than a Supplier - A Partner Manufacturers You Can Rely On

| Method | Description | Advantages | Considerations |

|---|---|---|---|

| Aerobic Composting | Utilizes oxygen to decompose organic materials. | Faster decomposition, higher quality compost. | Requires regular turning to maintain oxygen levels. |

| Anaerobic Digestion | Breaks down organic material without oxygen, producing biogas. | Produces renewable energy and reduces methane emissions. | Requires specific conditions and can be costly to set up. |

| Vermicomposting | Uses worms to break down organic waste into a nutrient-rich soil amendment. | Produces high-quality compost; low maintenance. | Limited to smaller scale operations; sensitive to environmental conditions. |

| Static Pile Composting | Compost is left in a pile and allowed to decompose. | Simple setup; minimal labor required. | Longer composting time; needs good drainage. |

| Windrow Composting | Organics are piled into long rows (windrows) and turned regularly. | Efficient for large volumes; aeration promotes faster composting. | Requires space and machinery for turning. |

Methods To choose Large Scale Composting Facility Your End-to-End Solution Industry Giant

S

Susan Parker

Fantastic quality! I appreciated the follow-up calls from their support staff—they truly care about customer satisfaction.

29 May 2025

D

David Lee

Highly satisfied with my purchase! The customer service team displayed great knowledge and professionalism throughout.

10 May 2025

N

Nancy Hughes

The quality impressed me instantly! The customer service was professional and attentive.

21 May 2025

K

Kevin Price

Impressed by the quality! Their after-sales service was professional and quick.

05 June 2025

F

Finn Martinez

Great quality product! Their customer service team showed great attention to detail.

03 June 2025

S

Steven Price

Incredible quality! The support staff was very professional and informative.

28 May 2025

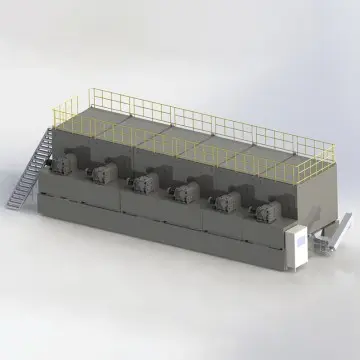

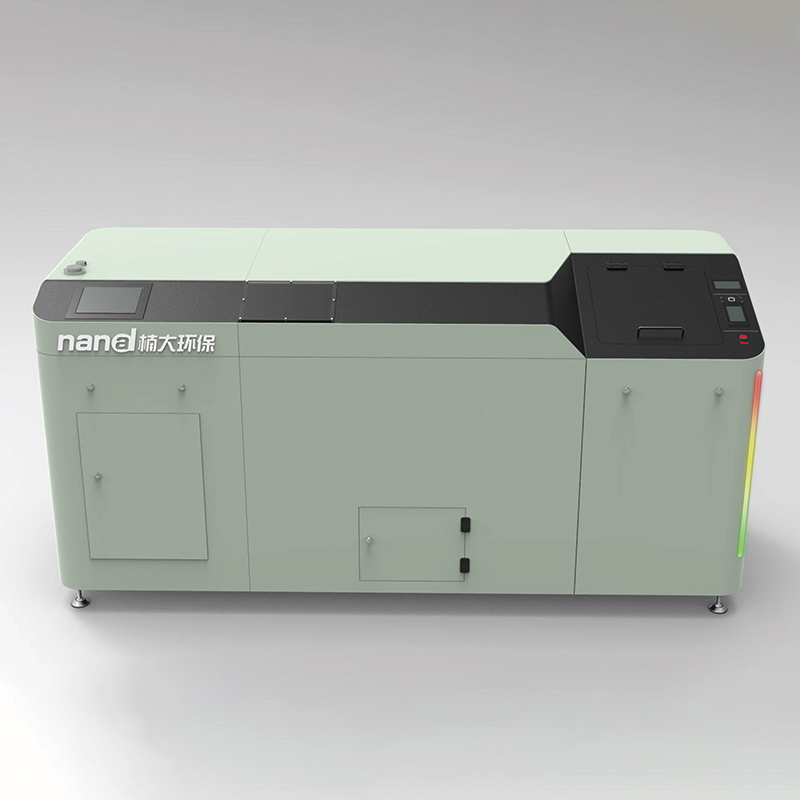

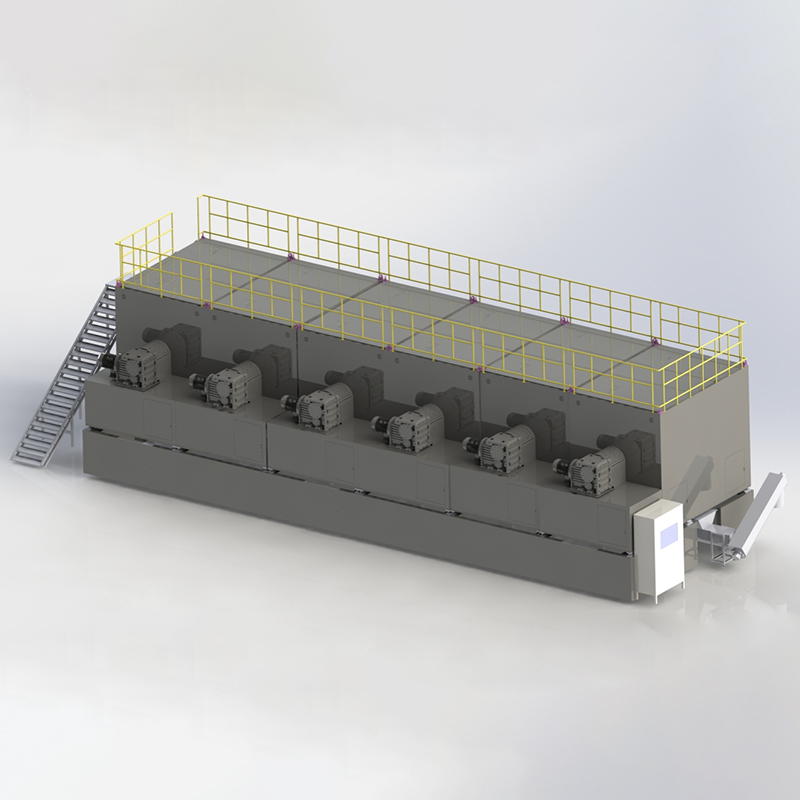

Nanda Trans Series-200

Nanda Trans Series-200 Nanda Trans Series-500

Nanda Trans Series-500 Nanda Trans Series-1000

Nanda Trans Series-1000 Nanda Trans Series-30000

Nanda Trans Series-30000 Nanda Thermax Series-100

Nanda Thermax Series-100 Nanda Thermax Series-200

Nanda Thermax Series-200 Nanda Thermax Series-2000

Nanda Thermax Series-2000 Nanda Thermax Series-10000

Nanda Thermax Series-10000 Nanda Turbo Series-3.5L-016

Nanda Turbo Series-3.5L-016 Nanda-Turbo Series-4L-011

Nanda-Turbo Series-4L-011 Nanda Turbo Series-4L-012

Nanda Turbo Series-4L-012 Oil-Water Separator

Oil-Water Separator